MPX-E | Explosion Proof and Non-Incendive Float Magnetostrictive Level Sensor

$10,000.00 USD

PRODUCT INFO

Monitor liquid levels with a float sensor and a ControlByWeb® module. Receive text/email alerts when a user-specified level is reached. Log and graph a tank’s level data over time.

How do Float Sensors Work

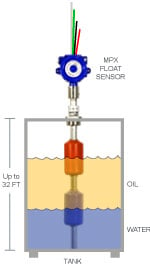

Magnetostrictive liquid level sensors consist of a float that moves up and down a stem, or rod. The float contains a permanent magnet, and the stem houses a wire waveguide that creates a magnetic field, making it possible to detect the floats position on the stem.

An electrical pulse travels down the waveguide, magnetizing it. When the pulse meets the magnetic field from the float, a vibration, also called a strain pulse, travels back to the sensor housing.

The Float sensor then measures the difference in time between the initial pulse, and the strain pulse, giving it an accurate and continuous reading of the tank's current level.

Liquid Types

Float Sensors work well with clean and dirty liquids, as they are customizable for almost any application.

1. Float Sensor Benefits

- Easy to install.

- Provide the most reliable and accurate method of level monitoring.

2. Sensor Ranges

- MPX float sensors are customizable for monitoring up to 32 ft with multiple float sensors.

3. Sensor Accuracy

- Sensors are accurate within 0.05% of its detected range.

Sensor Output

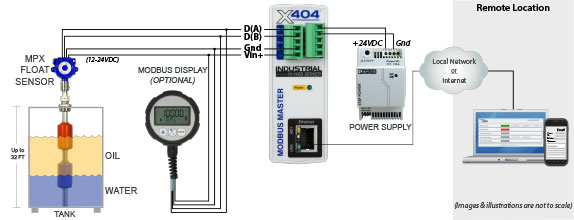

- Modbus RS-485

Easily configure sensor data using the X-404 Modbus Master Controller. No voltage scaling required! - 4-20mA

For exisiting systems that require 4-20mA, connect the sensor to one of our compatible devices (X-418, X-420, X-22s).

Recommended Installation

Top of Tank

Carefully lower the MPX Float Sensor into the tank, then secure the sensor to the tank. If the floats don't fit through the mounting hole, remove the floats and connect the floats from the inside of the tank after the stem has been lowered through the mounting hole.

Remote Monitoring

Each float sensor can be connected to a ControlByWeb module to remotely monitor liquid levels in real-time using a standard web browser or mobile device. Liquid levels can be presented to the user as a simple liquid height measurement, or the module can be configured to calculate the volume of liquid used or the volume remaining in the tank and present that to the user. No special software required.

Remote Control & Monitoring

In addition to simple remote monitoring, ControlByWeb modules are fully programmable and provide custom control capabilities as well. For example, you can connect a pump to a relay on a ControlByWeb module and remotely run the pump manually, or configure the pump to automatically run if the level gets too low.

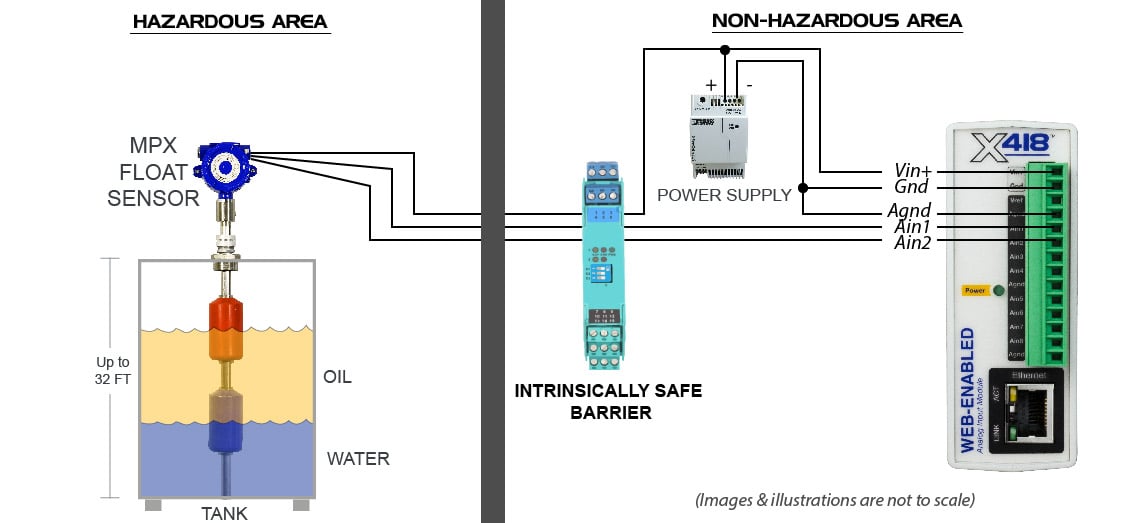

Level Monitoring in Hazardous Environments

Warning: Use of these products to monitor tank levels of potentially explosive liquids or substances (such as gasoline), requires strict adherence to local safety laws and regulations. ControlByWeb modules (such as the X-404, X-420, etc) are NOT designed to be intrinsically safe and must be installed with both physical and electrical safety barriers. Installation should only be performed by qualified individuals and companies who understand the safety requirements. Please refer to sensor installation manuals and consult local safety regulations for more information.

Intrinsically Safe - Modbus Monitoring

Intrinsically Safe - 4-20mA Monitoring

SPECIFICATIONS

| Performance | |

| Resolution | 4-20 mA: 14 bit DAC Modbus: 0.04 in. (1mm) |

| Accuracy | ±0.05% of full scale |

| Environmental | |

| Operating Temperature | -40º - 185ºF (-40º - 85ºC) |

| NEMA 4X, IP65 | |

| Physical | |

| Housing | Cast aluminium, epoxy coated |

| Stem Length | 1 - 12.75 ft. (0.3 - 3.9 m) |

| Stem | 0.5” ø 316L SS |

| Electrical | |

| Electrical Connection | Terminal Block, 12-24 VDC |

| Total current draw | 4-20 mA: (single) 22 mA, (dual) 44 mA Modbus (RS-485): 25 mA |

| Connectivity | |

| Output | Single or dual loop-powered 4-20 mA Modbus RTU (RS-485) with optional Temperature output |

| Certification | |

| NEMA 4X, IP65 CSA: Class I Division 1 Groups C & D T4 (Ta 85°C); Class I Division 2 Groups C & D T4 (Ta 85°C); Class I, Zone 1; AEx d IIB T4; Class I, Zone 2; AEx nA IIB T4; Ex d IIB T4; Ex nA IIB T4 | |

HVAC

HVAC

Plumbing

Plumbing

ELECTRICAL

ELECTRICAL

Tools & Test Instruments

Tools & Test Instruments